Glass & sapphire glass CNC machining possesses several properties that make it a popular method for shaping and fabricating glass & sapphire glass components. Here are some key properties associated with glass & sapphire glass CNC machining:

Precision

CNC machining offers high precision and accuracy, allowing for tight tolerances and precise dimensions to be achieved on glass components. The computer-controlled system ensures consistent machining according to the programmed design, resulting in precise and repeatable results.

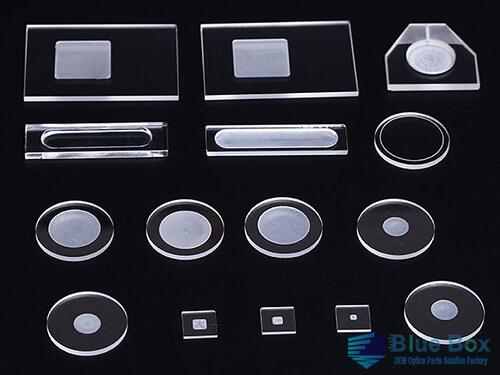

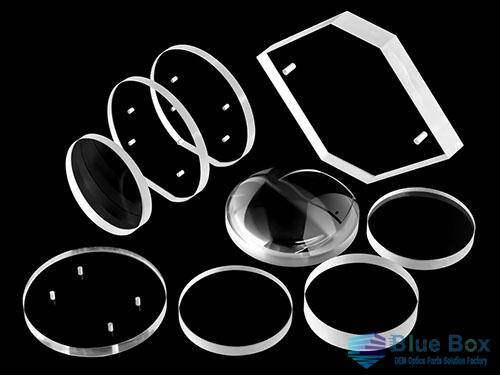

Versatility

Glass CNC machining is versatile and can be applied to various types of glass, including float glass, tempered glass, laminated glass, and specialty glass. It can accommodate different glass thicknesses and sizes, making it suitable for a wide range of applications.

Customization

CNC machining allows for customization and flexibility in design. The programming stage enables easy modifications and adjustments to the design without requiring physical tool changes, allowing for quick prototyping and customized glass components. Complex shapes, intricate details, and specific features can be easily achieved.

Efficiency

CNC machining is an efficient process for shaping glass components. The automation of the process enables fast and precise material removal, reducing production time and increasing productivity. Additionally, the use of computer programming and advanced tooling minimizes manual labor requirements.

Surface Finish

Glass CNC machining can produce smooth surface finishes on glass components. The cutting tools used in CNC machining can be selected to achieve desired surface quality, whether it's a polished, satin, or textured finish. Additional finishing steps, such as polishing or surface treatment, can also be employed to further enhance the appearance and smoothness of the glass.

Complex Shapes and Features

CNC machining enables the creation of complex shapes, intricate details, and precise features on glass components. Three-dimensional contours, curved surfaces, internal cutouts, holes, threads, and intricate patterns can be achieved with high precision, allowing for greater design possibilities.

Material Preservation

CNC machining minimizes material waste due to its precise material removal capabilities. The machining process removes only the necessary material, resulting in minimal material loss and optimized material usage. This efficiency helps reduce production costs and optimize material resources.

Scalability

CNC machining is a scalable process, allowing for both small-scale production runs and large-scale manufacturing. The programmed instructions can be replicated for multiple glass components, ensuring consistency and accuracy across the production batch.

Automation and Integration

CNC machining can be integrated into automated production systems, offering enhanced efficiency and productivity. It can be linked with other manufacturing processes, such as CAD design, quality control systems, and robotic handling, to streamline the overall production workflow.

Inquire Us